Industrial Pond Aerators & Circulators

High Volume

Moving an impressive 3.3lbs or 1.5kg of oxygen per horsepower hour and pumping over 900GPM or 198 m3/hour, Otterbine’s experience in wastewater treatment is obvious in the performance and results delivered by the High Volume Industrial Aerator. Constructed from stainless steel, thermoplastics and a rugged low speed motor; this system is built to withstand the demands of severe aquatic environments.

Video

High Volume Industrial Pond Aerator

Moving an impressive 3.3lbs or 1.5kg of oxygen per horsepower hour and pumping over 900GPM or 198 m3/hour, Otterbine’s experience in wastewater treatment is obvious in the performance and results delivered by the High Volume Industrial Aerator. Constructed from stainless steel, thermoplastics and a rugged low speed motor; this system is built to withstand the demands of severe aquatic environments. Systems range in size from 1HP-5HP.

Features:

Our most powerful aerator, the High Volume is chosen for its rugged design and its impressive oxygen transfer and pumping rates. Meeting the demands of severe aquatic environment and backed by a comprehensive 3-year warranty, check out some of the other features it offers:

Energy Efficient

Low amperage systems mean less electrical consumption and low running costs.

Proven Performance

Otterbine is the only manufacturer to have oxygen transfer and pumping rates independently tested and published on their aeration systems. The High Volume offers the highest oxygen transfer and pumping rates in the industry.

Versatile

Suitable for use in a variety of applications from wastewater treatment to effluent ponds.

Complete Package

Most systems come complete with unit, power control center, and cable with cable quick disconnect for ease of installation.

Shallow Operating Depth

The High Volume operates in 32in or 81cm.

Safety Listed & Protected

Package electrically safety tested and listed with ETL, ETL-C. Products for European Union are also safety tested, approved and carry a 3rd party independent CE mark.

Product Specifications: High Volume

| 60Hz | 1HP | 2HP | 3HP | 5HP | Spray Height (ft) | 1.5 | 2 | 3 | 4.5 |

|---|---|---|---|---|

| Spray Diameter (ft) | 4 | 7 | 9 | 11 |

| GPM | 920 | 1525 | 2100 | 3000 |

| Voltage/Phase/Amp 1725rpm@60Hz | 115/1/13.4 230/1/6.8 | 230/1/11.9 | 230/1/13.5 230/3/8.5 460/3/4.2 | 230/3/14.4 460/3/7.5 |

| 50Hz | 1HP | 2HP | 3HP | 5HP | Spray Height (m) | .5 | .6 | .9 | 1.1 |

|---|---|---|---|---|

| Spray Diameter (m) | 1.2 | 2.3 | 2.6 | 3.5 |

| m3/hr | 198.5 | 329 | 453.1 | 647.2 |

| Voltage/Phase/Amp 1425rpm@50Hz | 230/1/8 | 230/1/12 | 230/1/14 400/3/4.2 | 400/3/7.2 |

Unit Construction

Otterbine Industrial Aerators have been designed and engineered by expert craftsman to provide a high quality, ease of use product that delivers results in severe aquatic environments.

Corrosion Resistant:

Components are manufactured of 18 gauge/316 stainless steel or thermoplastics to withstand the demands of severe aquatic environments & can be used in brackish and effluent conditions.

Easy Handling:

Protective arms secure motor unit and allow for easy handling.

Rugged Design:

Protective arms secure unit, while a low-speed custom built motor with dynamically balanced rotors is designed to move high volumes of water and perform in severe aquatic environments.

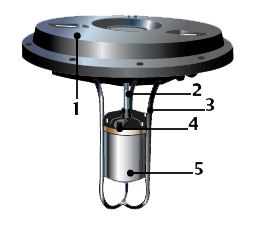

Unit Illustration

-

1

Rugged closed cell foam filled low visibility polyethylene float.

-

2

Precision pitched stainless steel impeller is virtually unbreakable.

-

3

Protective arms secure motor unit and allow for easy handling.

-

4

Electrical disconnect is part of upper plate to prevent accidental damage.

-

5

Enclosed in a corrosion resistant, durable 18 gauge/316 grade stainless steel motor housing, the oil-cooled, efficient 1725/1425 RPM custom built motor has dynamically balanced rotors to move high volumes of water.

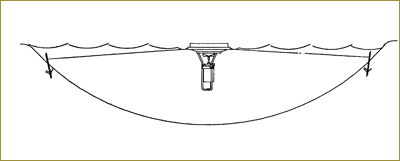

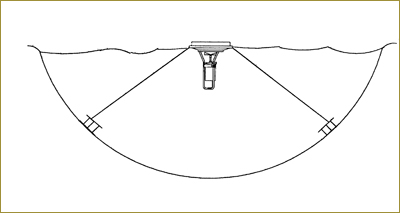

Installation

The High Volume arrives partially assembled and installation can be performed in just a few steps.

-

1

Install Power Control Center: Power control center is mounted onshore; a certified electrician is recommended to perform this step.

-

2

Lay Power Cable: Bury/trench power in conduit to pond edge, connect plug to unit.

-

3

Float System in Water & Anchor/Moor into Place: Depending on method selected, the use of a boat may be required.

Maintenance & Winterization

Maintenance

Otterbine High Volume units require minimal maintenance, to insure years of dependable service we recommend the following:

-

1

Once a year: Disconnect unit from power and physically inspect aerator, float and electrical cable.

-

3

Every three years: An oil change is suggested to keep your aerator running smoothly.

Winterization

These units can remain in the water during the winter but need to run 24 hours per day to keep the unit from freezing in.

The Most Powerful Aeration When You Need It

Producing the Highest Pumping & Oxygen Transfer Rates in the Industry to Effectively Manage Severe Aquatic Environments!