Lighting & Accessories

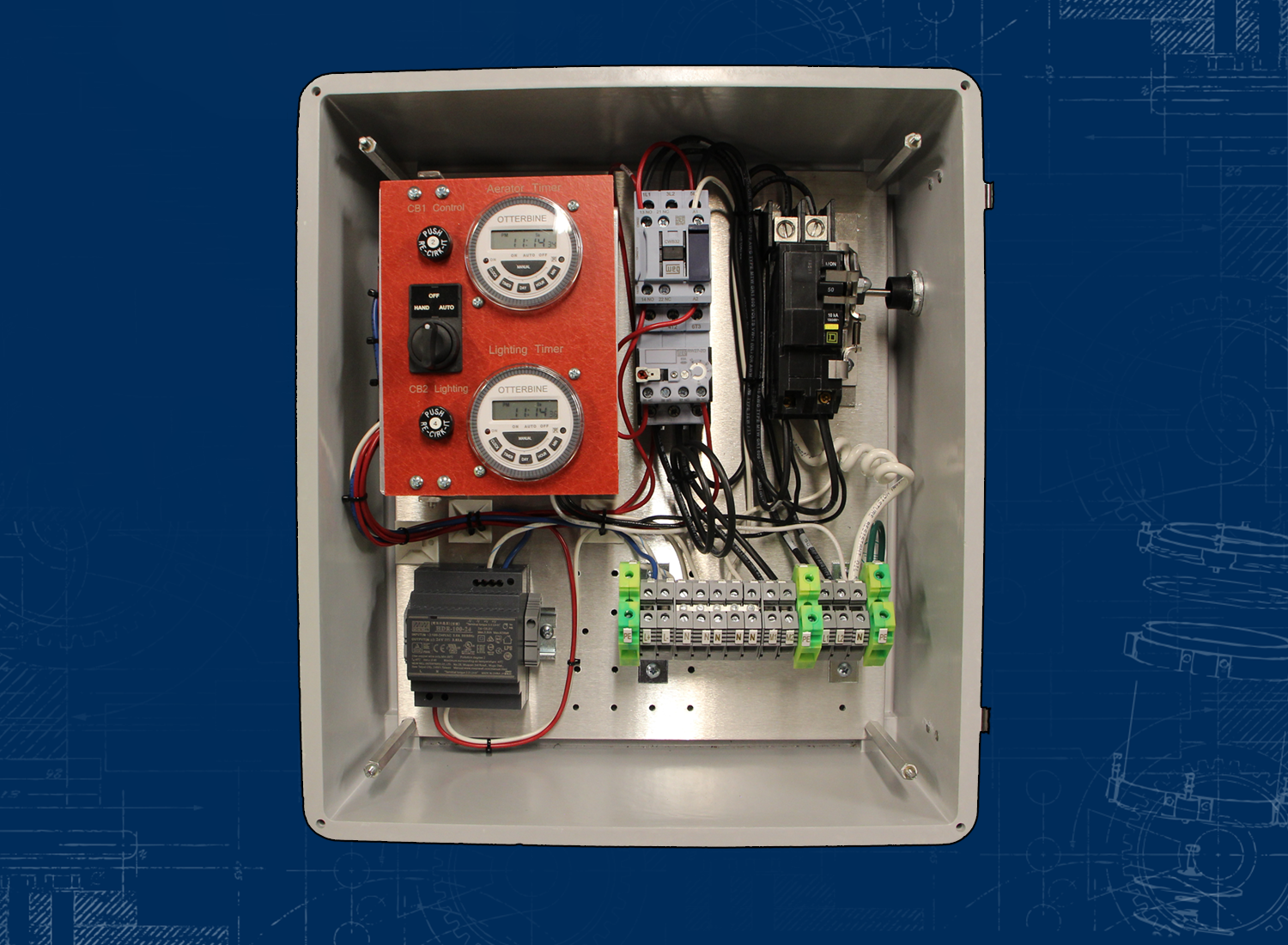

Power Control Center

The quality and integrity of our Power Control Center speaks to our commitment of remaining the safest and most reliable product on the market. All of Otterbine's Power Control Centers, Units, and Cable are safety listed with ETL and CE. Both Single Phase and Three Phase panels accommodate easy service and installation!

Features

Otterbine is the ONLY fountain manufacturer to provide people protection in all of our panels regardless of the horsepower, voltage, or phase! This means all of our panels trip at 5 milliamps to ensure that everyone stays safe while enjoying beautiful waterways. Power control centers come standard with all North American packages.

• Single Phase Panels: 16IN x 18IN x 6IN (41CM x 46CM x 15CM)

• Three Phase Panels: 18IN x 20IN x 9IN (46CM x 51CM x 23CM)

State of the Art Components

Surge/lightning arrestor, digital timer, manual-off-auto switch, motor controller, external reset and people protection GFCI are all provided in our power control centers.

Safety Listed & Protected

All components meet National Electric Code standards, are UL listed and CSA certified. Aerator/Fountain, PCC, and all components are ETL and CE listed and approved as a complete package.

Fiberglass Enclosure

Our standard cabinet is a non-corrosive, durable NEMA 4X fiberglass enclosure.

Comprehensive Warranty

All-inclusive warranty on panel and controls (warranty period correlates to the product line associated with power control center).

Custom Controls

As a certified panel building workshop Otterbine offers custom power control center options that can control multiple systems in one panel, in addition to a variety of other options.

Panel Options

Add convenience or increase efficiency by including additional components such as wind controls, photocells, light sets, phase monitors, step down transformers, and more.

Unit Construction

Units are sized at 16IN x 18IN x 6IN (41CM x 46CM x 15CM) for Single Phase and 18IN x 20IN x 9IN (46CM x 51CM x 23CM) for Three Phase power.

Corrosion Resistant

All standard enclosures are manufactured from durable fiberglass and are NEMA 4X rated and resist deterioration in corrosive environments.

Convenient

Larger designs make for easy installation and service! Panels for 1HP-5HP systems incorporate an internal “swing panel” for quick and easy access to more commonly used components such as the timer and GFCI.

Customizable

Built to order, these panels can be customized to include multiple units and other controls to meet the needs of your installation.

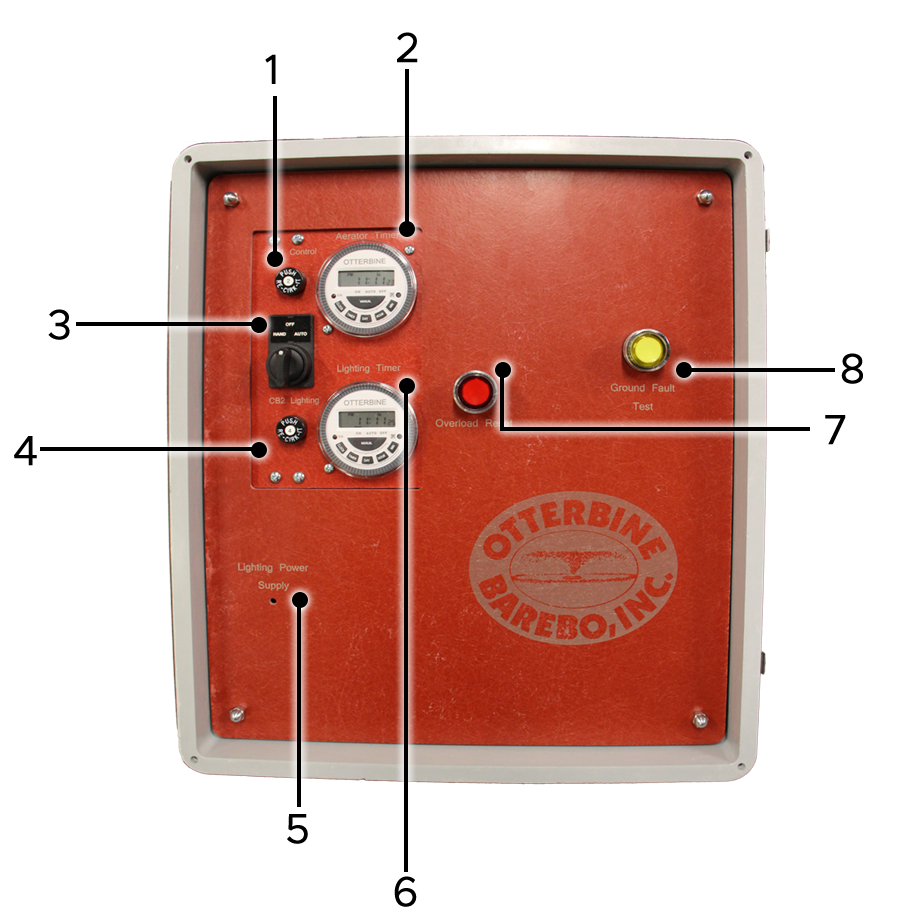

Unit Illustration

-

1

Swing Panel - convenient access to regularly accessed items; while wiring and other components can be accessed behind on the sub-panel.*

-

2

24/7 Digital Timer Aerator/Fountain - standard with Otterbine’s 1HP-25HP aerator/fountain power control centers.

-

3

HOA Switch - change from hand timed/manual mode to auto.

-

4

Control & Lighting Circuits - easy to reset.

-

5

Lighting Power Supply

-

6

24/7 Digital Timer Lighting - not ready to purchase lights? Otterbine offers the option to have light controls installed in your panel from the get-go so adding lights later is easier than ever!

-

7

Overload Reset - if your unit overheats or overloads this safety device will shut the motor off.

-

8

Ground Fault Test - detect system grounding points to ensure that no ground paths occur that would sidestep the sensors

*True for most aerator/fountain system PCC’s; exceptions may occur for 1/2HP

panels and Giant Fountains.

Installation

Having operational electricity is necessary before flotation and start-up of any aeration system, and a power control center (PCC) will be needed. A certified electrician will be required for the installation of the electrical panels, and may become a scheduling consideration throughout the installation process. Be sure to follow both local and national electrical codes during installation.

-

1

Determine Panel Location PCC should be installed above high water line (HWL) and within line of sight of aerator/fountain. Consider aesthetics of landscape when choosing location.

-

2

Tighten Connections Insure all component connections are tight, some may become loose during transit.

-

3

Connect Power A certified electrician should perform this step, wiring schematics are provided with all new products.

Maintenance

Maintenance

The Power Control Center (PCC) require minimal annual maintenance. Simply be sure to keep the inside of the panel clean and dry, and on a regular basis test the GFCI for proper function.